- All the products

- Oil and Gas industry

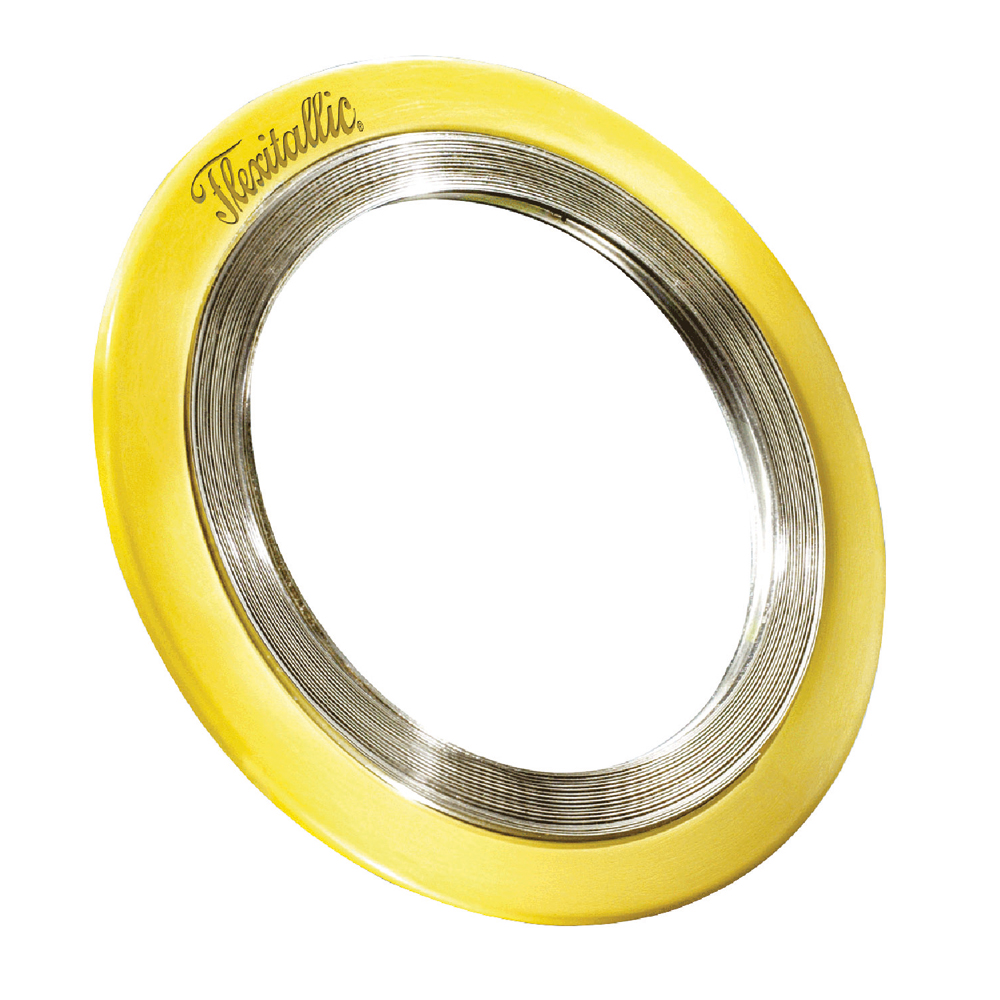

- Spiral wound gaskets

Spiral wound gaskets

https://texascontrols.com/shop/spiral-wound-gaskets-17434 https://texascontrols.com/web/image/product.template/17434/image_1920?unique=33b2c11Effective sealing solutions for increasingly demanding applications.

-

Flexibility and recovery To cope with the effects of high pressure, wide temperature fluctuations and bolt relaxation

CG STYLE

+ Style CG gaskets: sealing element + outer metal ring.

+ Outer ring: Positions gasket, prevents excessive compression.

+ Design ensures optimal sealing performance.

+ Suitable for raised and flat faced flanged connections.

+ Appropriate for mild to moderate service conditions.

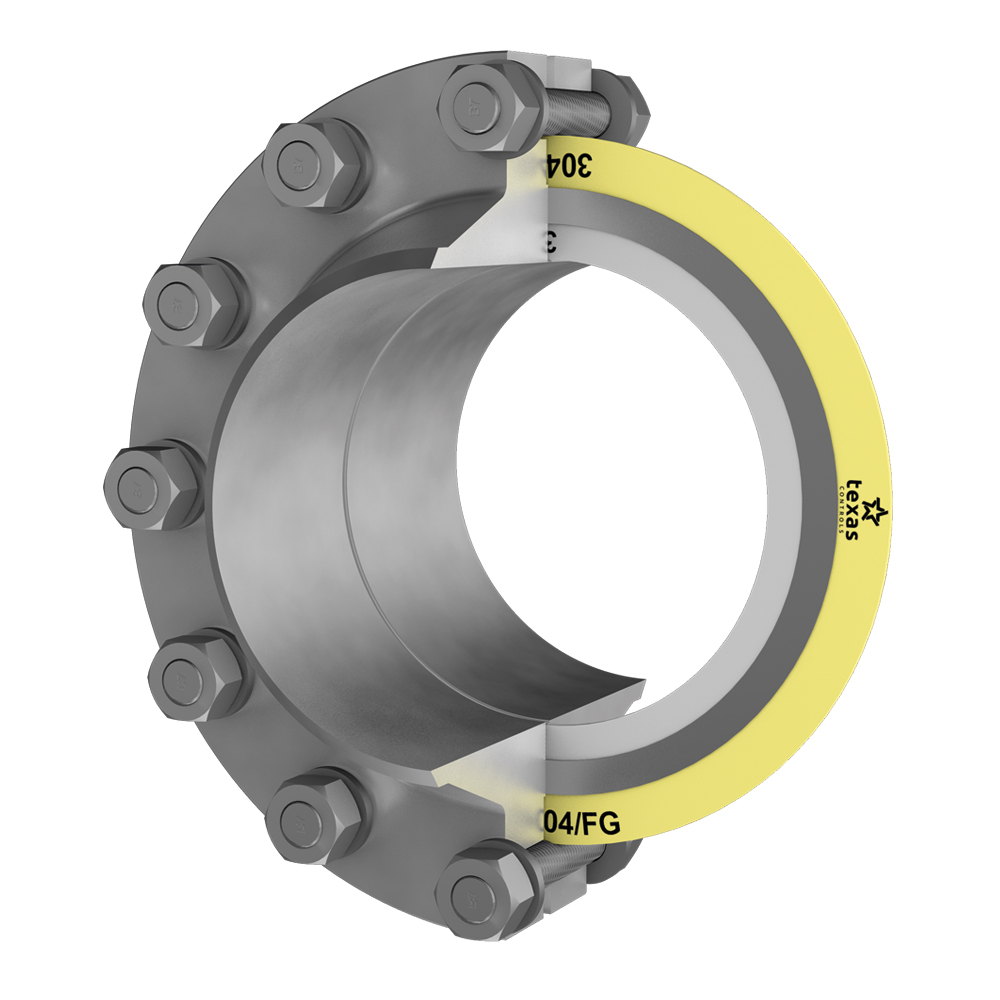

CGI STYLE

+ The CGI style gasket consists of an outer metal ring and an inner metal ring.

+ The inner metal ring prevents the sealing element from buckling and acts as an additional compression stop.

+ It also acts as a barrier between the sealing element and the process stream, protecting it from heat, media, and erosion.

+ CGI gaskets can be used on raised and flat faced flanged connections.

+ They are suitable for moderate to severe service conditions.

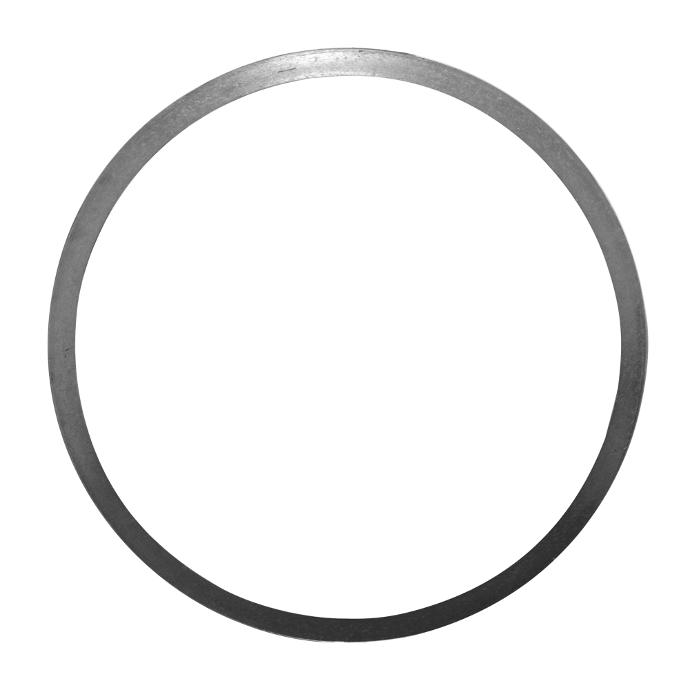

R STYLE

+ The gasket is made up of a sealing element and additional plies of metal at the beginning and end of the winding process.

+ The extra metal layers enhance stability and sealing performance.

+ Unlike other spiral wound gasket styles, compression of the sealing element is regulated by the appropriate flange face configuration.

+ Style R gaskets can be used on tongue and groove, male and female, and flat to groove flanged connections.

RIR STYLE

+ The gasket consists of a sealing element and an inner metal ring.

+ The inner ring serves as a compression stop and forms a physical barrier between the sealing element and the media stream.

+ It also reduces turbulent flow, preventing flange erosion and the accumulation of debris in the annular space.

+ Style RIR gaskets are appropriate for male and female (spigot and recess) flanged connections.

- + Thermiculite® is often used as a filler material to provide resistance to temperature, chemical attack and corrosion.

- + Significant stock holding of standard gaskets.

- + Flexibility to manufacture and supply gaskets with a combination of inner and / or outer guide rings.

- + Wide range of machinery that enables us to manufacture any size gasket.

- + Custom designs available.

- + World-class testing and development centre.

- + Spiral wound gaskets are found in a host of applications across the world, from small diameter turbine gaskets, to HP heat exchangers.

Specifications for Spiral wound gaskets

| Gasket range | CG Style or CGI Style or R Style or RIR Style |