With BoltPilot®, we automate the bolt tightening operations for greater efficiency

With our BoltPilot software, we have managed to improve the productivity of companies involved in the assembly and operation of wind farms, leading to a reduction in working time and minimizing incidents due to procedure failures. Speak to one of our experts to implement it in your company.

BoltPilot®: Smart Bolting System

Digitize the tightening processes with BoltPilot®, an integrated management system of software, hardware, and bolting tools working in unison.

30% + faster than traditional tightening

BoltPilot and sensorized tools reduce bolt tightening times by 30%.

Tighten according the procedure

BoltPilot ensures that the tightening is carried out according to the procedure

40% savings in maintenance

Maintenance can shift towards

a predictive approach

BoltPilot®: Operating guidance

and Real Time-Help

BoltPilot guides the operator during bolt tightening operations by sending preset bolting parameters to the tool, ensuring the precision of work and optimizing bolt tightening times compared to traditional methods.

The results are wirelessly captured automatically

(via WIFI, BLUETOOTH, RFID, QR, or RADIO)

BoltPilot: Multidevice

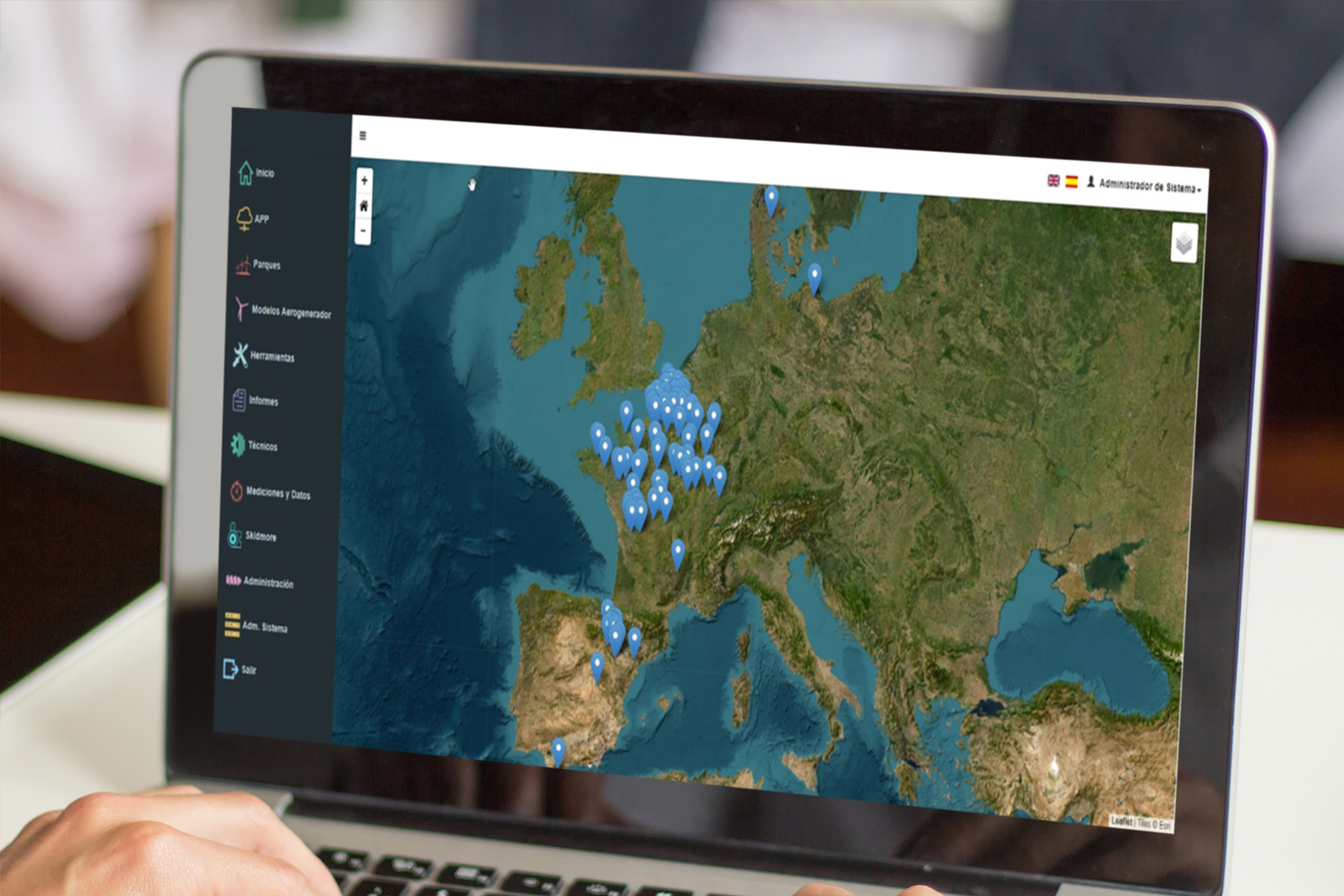

When the work is done in the field, we use connected devices such as smartphones, tablets to be able to serve as a bridge between the software BoltData, the tools and technicians that must carry out the work.

One-click access to each wind farm, turbine, and joint. Complete and certified traceability of the tightening process, ensuring best practices and excellence in work.

We are BoltPilot experts: Implementation in 4 Steps

The professionals at Texas Controls guide and advise you on the implementation and use of BoltPilot. We guarantee the training of your teams and offer excellent after-sales service. BoltPilot is easy to install and implement. It is configured in 4 simple steps and within five minutes.

We accompany you throughout the implementation process and provide on-site training:

- + Support throughout the implementation process

- + Training for operators in the field with specialized personnel

- + Technical support via phone and on-site

- + Consultancy on its use

Data integration

Entering wind farm data on the server and configuration of the work package

Deployment and On-Site Training

Deployment of sensorized tools on site, and training of workers in guided tightening

Data capture

Sensorized tools will automatically send data to the server

Operational control

Visualizes in real time all bolt tightening data for each turbine or wind farm: tools used, forces applied, joints, etc.

OUR SENSORIZED TOOLS INCLUDING BOLTPILOT®

Many of our tools are sensor-enabled and include BoltPilot®, but we also offer the possibility of adapting other tools to capture real-time data, as well as their rental.

Try our BoltPilot software. Request your trial version and additional information

We will prepare a customized demo for your industry. Discover our software and improve your productivity and efficiency.

BoltPilot®: EU 2020 Seal of Excellence

BoltPilot® is the result of years of research and development dedicated to improving efficiency and safety in the industry. This innovative solution revolutionized the way tightening is managed in the wind industry. With advanced automation and control features, BoltPilot® offers complete control over tightening processes: who, how, what, when, and where.

The acquisition of the European Commission's Certificate of Excellence is a testimony to the quality and impact of BoltPilot in the market. This recognition distinguishes Texas Controls as a leader in innovation and technology, demonstrating our commitment to the highest standards of quality and performance.